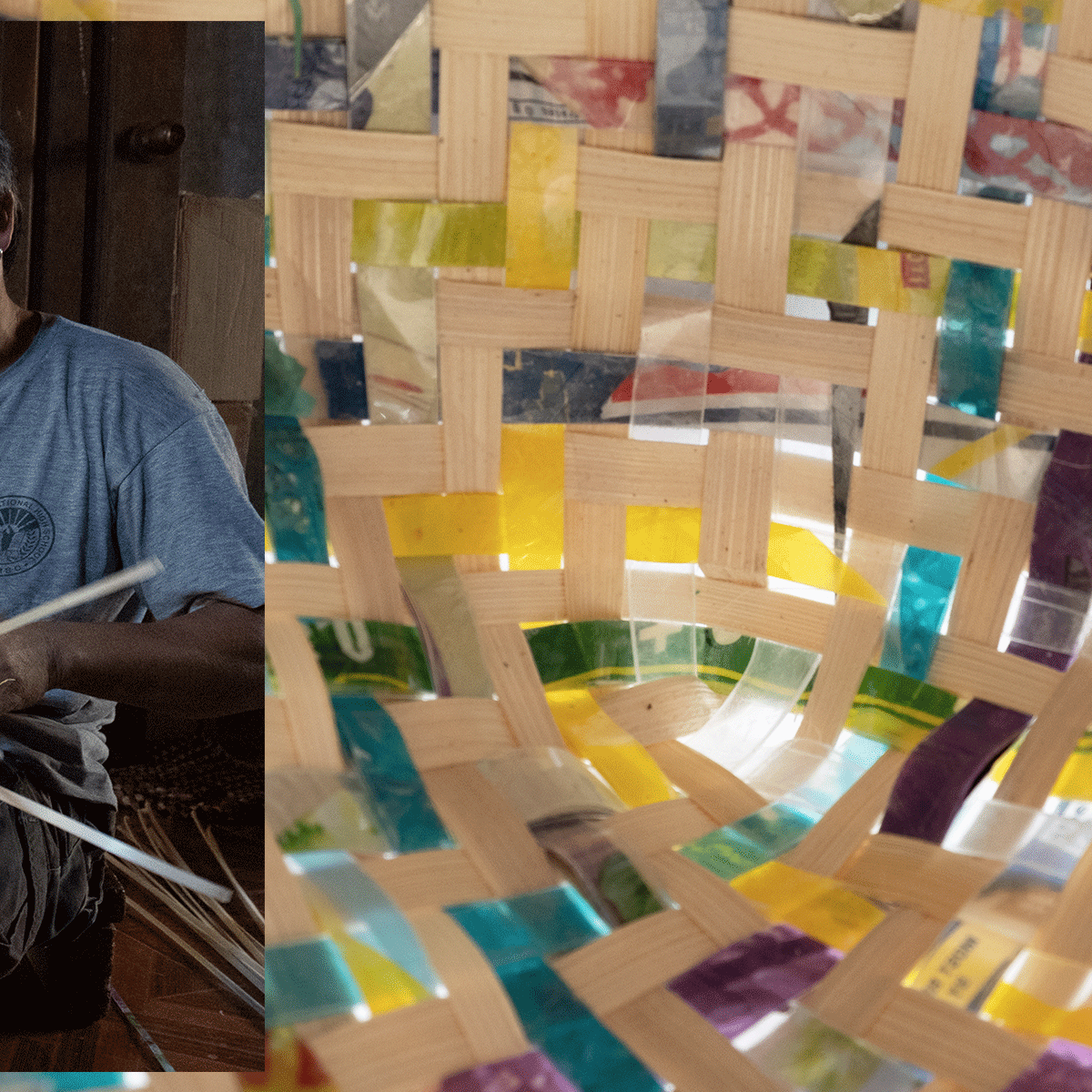

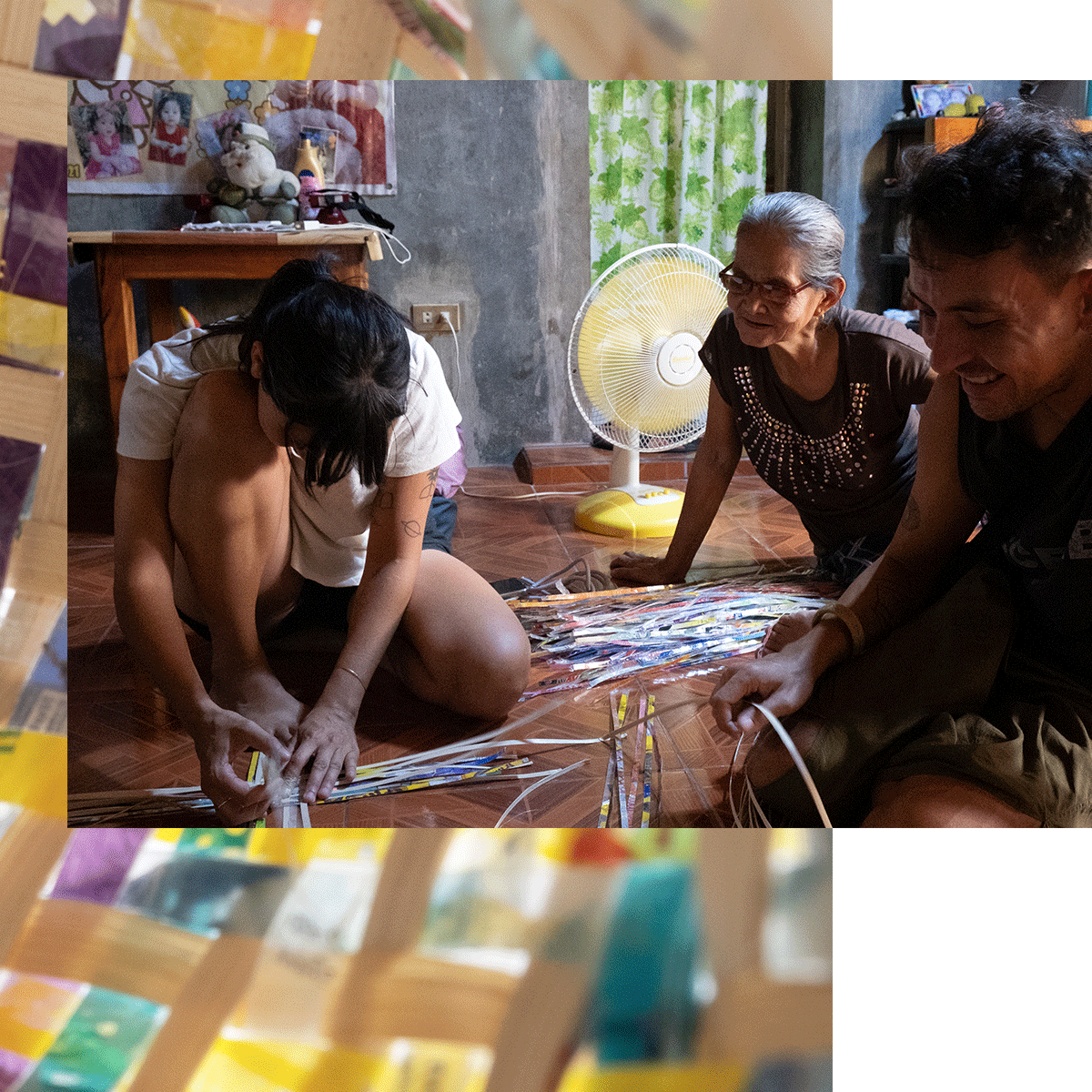

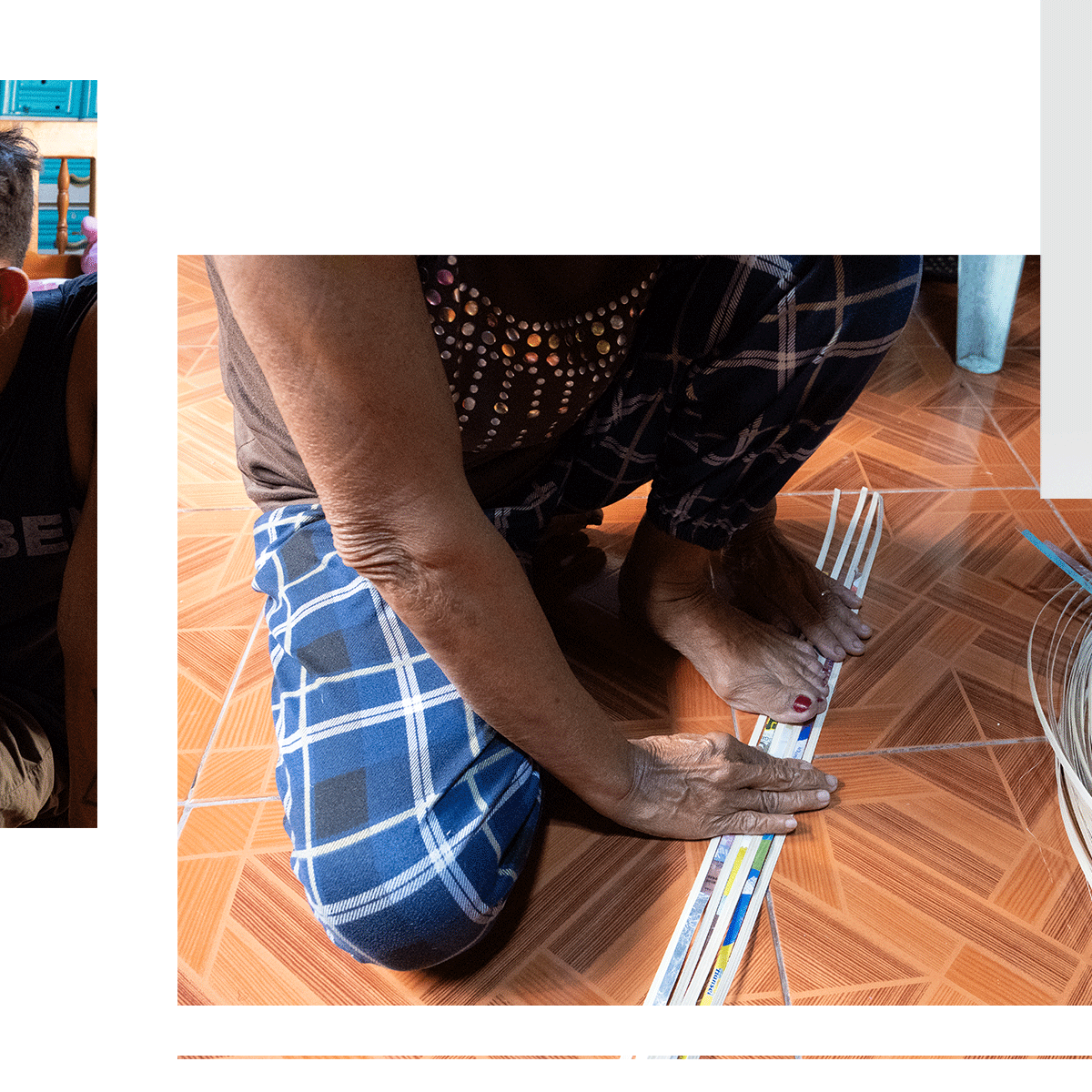

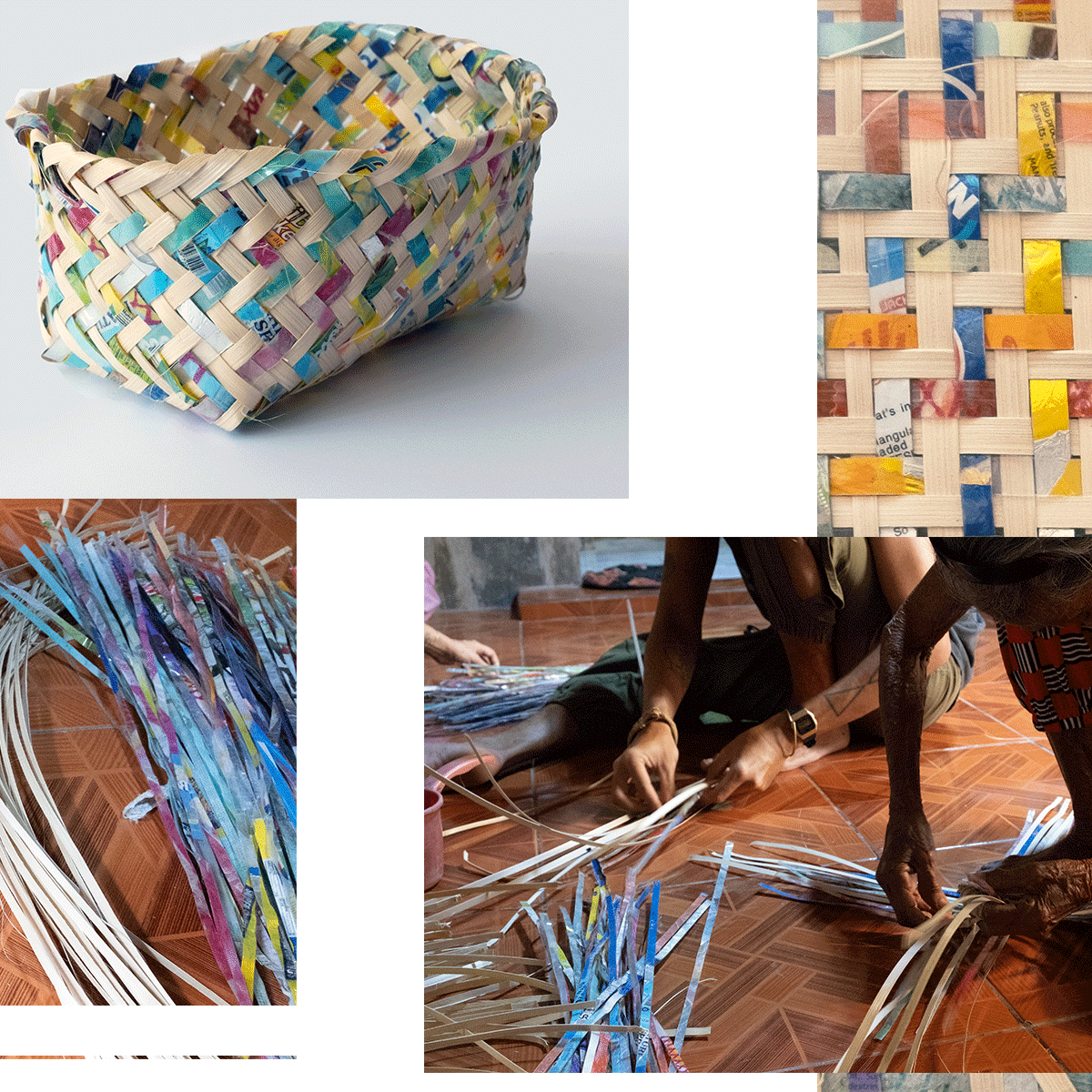

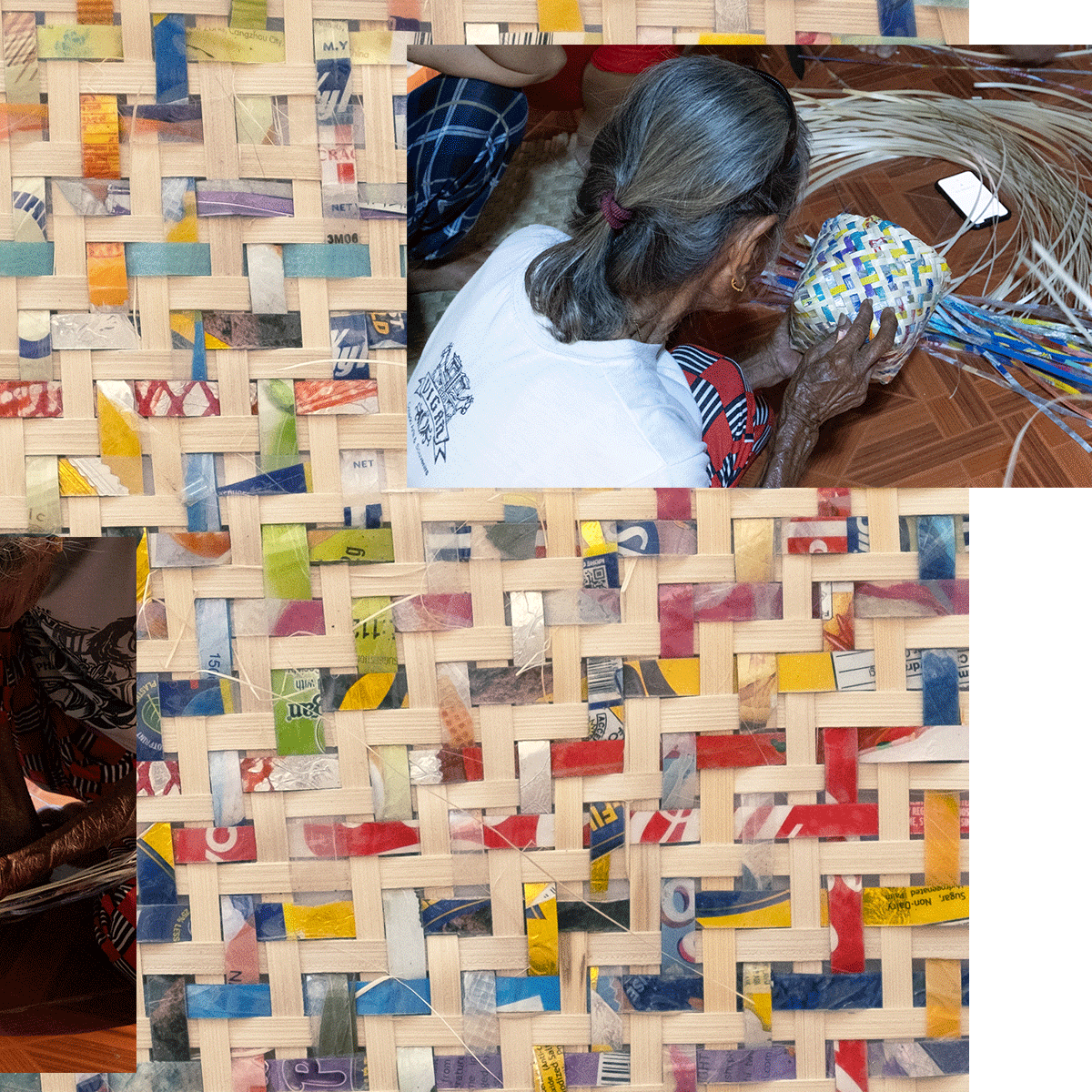

“alterlife” is an in progress research project that reaches across diaspora to homeland to engage with traditional material culture and ecological knowledge as a barometer to understand how climate crisis is transforming coastal island communities. Inspired by techniques of weaving mats for sleeping on from palm leaves (“banig”), this project features a series of objects co-created with the weavers of La Union, Philippines. Banig are revered throughout the Philippine diaspora; considered by some to be the most basic form of shelter, they are even distributed to survivors in the aftermaths of natural disasters. In this project, I learned the craft of weaving alongside the weavers, and I simultaneously collaborated with them to develop weaveable plastic strips from locally gathered marine litter. By empowering weavers as decision makers in the process of combining traditional organic materials with discards, and establishing them as equal owners of the processes we developed together, “alterlife” is necessarily grounded in an equal exchange. Responding to the notorious proliferation of plastic waste throughout the Philippines—a result of the “sachet economy” that capitalizes on a population with low, irregular income, and of having been used as a dumping ground for “recyclables” shipped in from wealthier nations—“alterlife” unites material and method to look at how we are all already co-constituted by our entanglement with “non-natural” materials like plastic. At the same time, “alterlife” also necessarily emphasizes the structural inequity embedded in climate crisis adaptation, a disparity that is deeply connected to unequal patterns of consumption between the global north and global south. It is from within this emergent framework that I look forward to developing future works.

This initial research phase was funded in part by a grant from The Puffin Foundation.

This initial research phase was funded in part by a grant from The Puffin Foundation.

In the past, I’ve couched the appearance of weaving in my work within the context of a “diasporic frame.” In this frame, weaving played a figurative role as a barometer for what I perceived as a dissolution or obsolescence in traditional craftwork, spurred on by the mechanisms of neoliberal policies and their effects such as climate crisis, land-grabbing and forced migration. But recently, spending more time with weavers has given me pause to reconsider that this might not be a story about dissolution and obsolescence, but about transformation and agency. The handful of encounters I had with the weavers of Sudipen was particularly generative for me specifically because they don’t weave banig—the node of Filipino material culture where my work has been situated for the past few years. In Sudipen, I met Louie, Felicidad and Violetta, a family of weavers who make baskets and trays from bamboo in their home, and they sell these wares at the local palengke as well as pasalubong shops. This difference gave me the space to drop my preconceptions and previous knowledge about weaving and to approach some big questions about my own engagement with traditional knowledge and ancestral handicraft with fresh eyes. One of my biggest fears, and the reason I established the “diasporic frame,” was out of my own anxiety around inadvertently reproducing colonial gaze and colonial relation across diaspora. After all, as Max Liboiron points out in their text “Pollution is Colonialism”: “people do not have to be jerks to maintain and reproduce colonial relations—they can have benevolent environmental goals.” The exact question I’d been coming up against required me to ask how my project, my work, my practice and conceptual frameworks might actually be extractive, and sought to uncover what and how I could change those structures to cultivate more balanced, reciprocal relationships.

I’ve been dreaming about spending time with banig weavers in the Philippines for so long, and was finally able to do that in February 2023. As a precursor to some more in-depth work I hope to do in the coming years, I was able to visit a handful of local weavers in my grandparents’ province of Leyte. During my interviews and conversations with them, I learned so much about the socio-economic contexts of weaving—what weaving means to the weavers, the challenges and struggles they face, what keeps them going with weaving, and significantly: how weaving is changing with a changing climate. I’m in awe of what they’re able to do, the complexity of the patterns they hold in their minds and the sheer longevity of their practice. My meetings with the weavers were all so intimate, and they always welcomed me and my research companions into their small domestic weaving spaces. I was humbled by the generosity of the weavers: each was so eager to share their knowledge and open to answering my each of my questions thoughtfully without ever even having to stop weaving.

I have to pause here to say daghan kaayong salamat sa Chan Bacolod, instructor at Visayas State University, for all of his hard work in facilitating these preliminary visits! AND thank you to BCAEd students of Sir Chan as well, who helped to facilitate these visits as guides within their own communities.

Weavers

1. Himokilan Island, Leyte

2. Apid Island, Leyte

3. Nanay Libeth, Brgy. Plaridel, Leyte

4. Leya, Brgy. Plaridel, Leyte

5. Ate Perla, Brgy Plaridel, Leyte

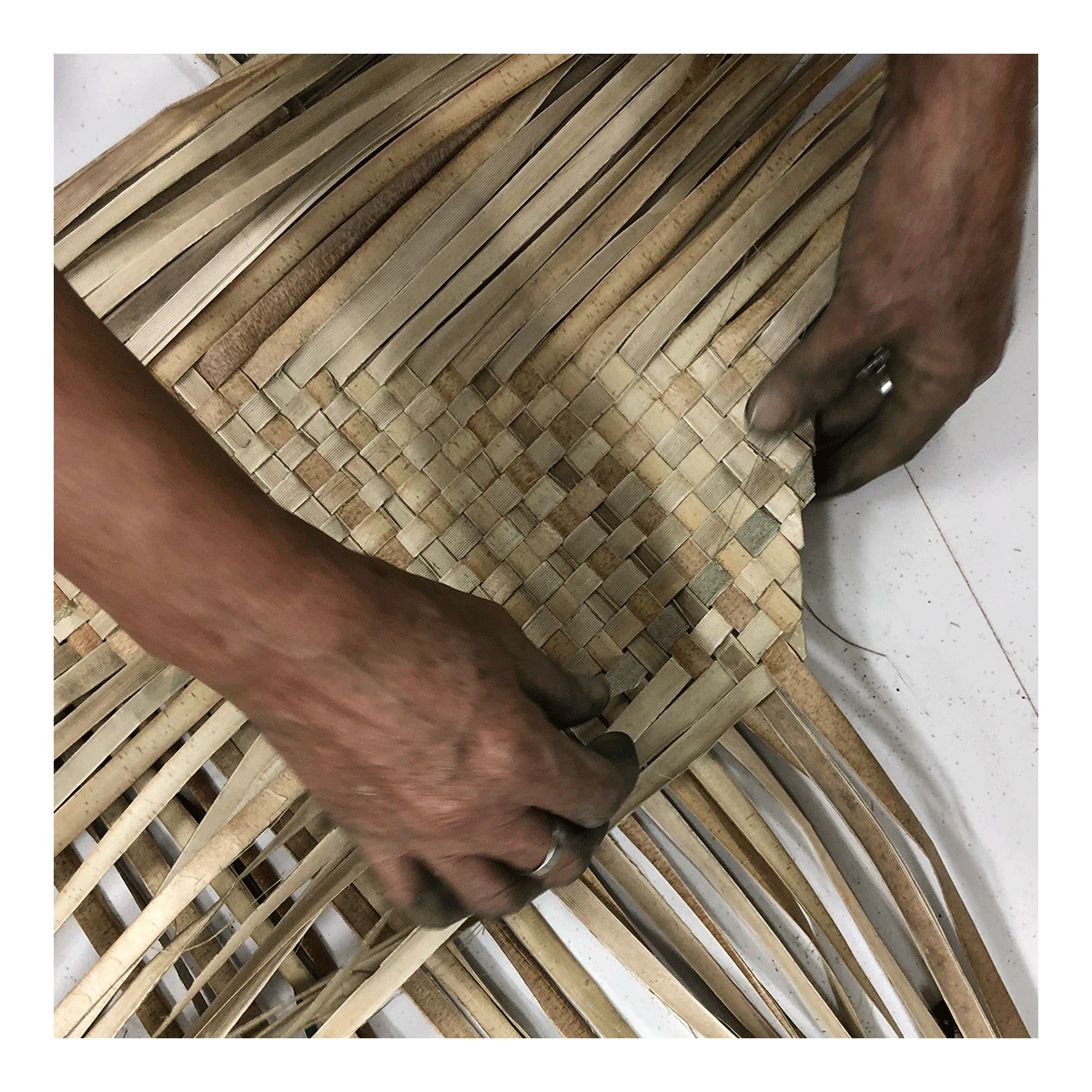

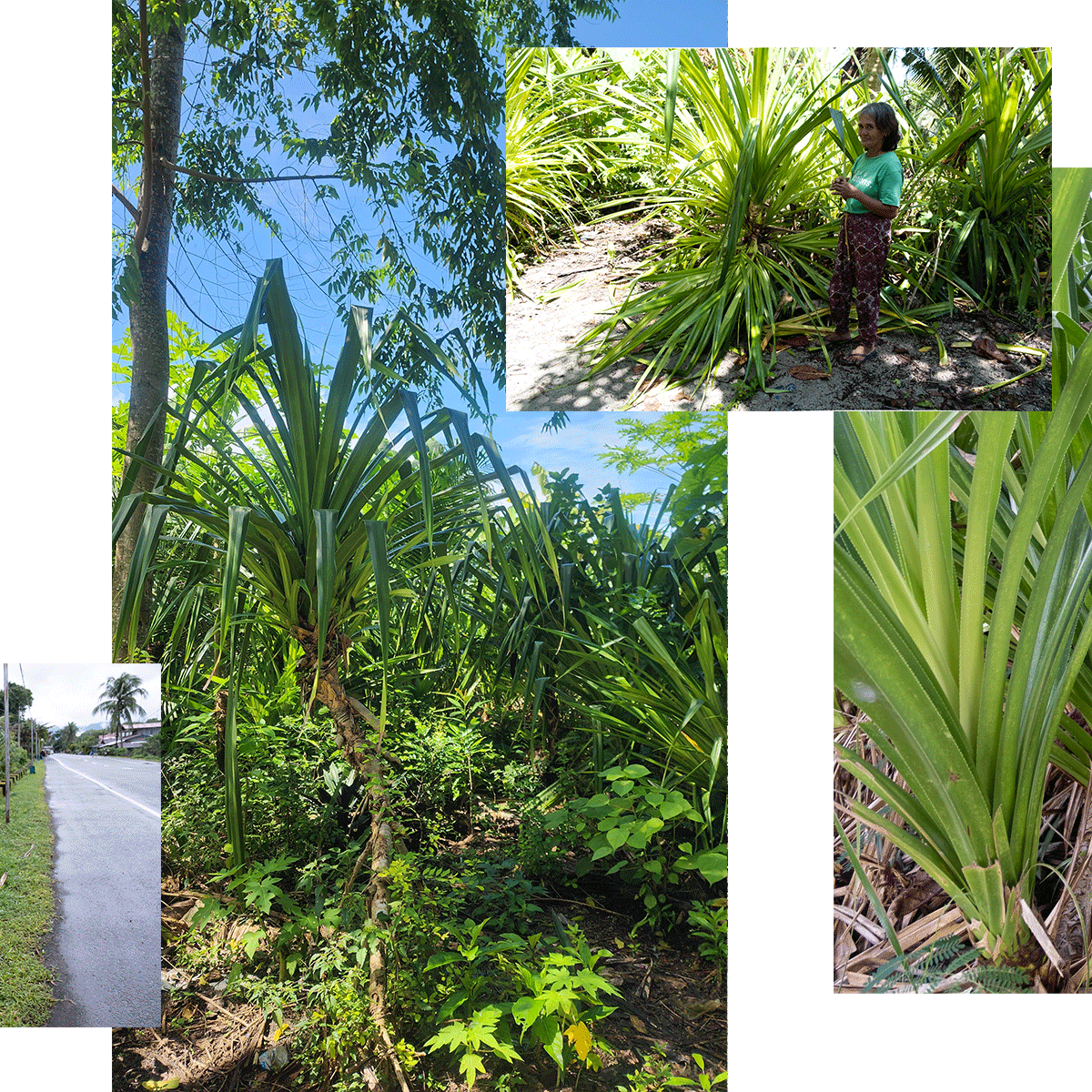

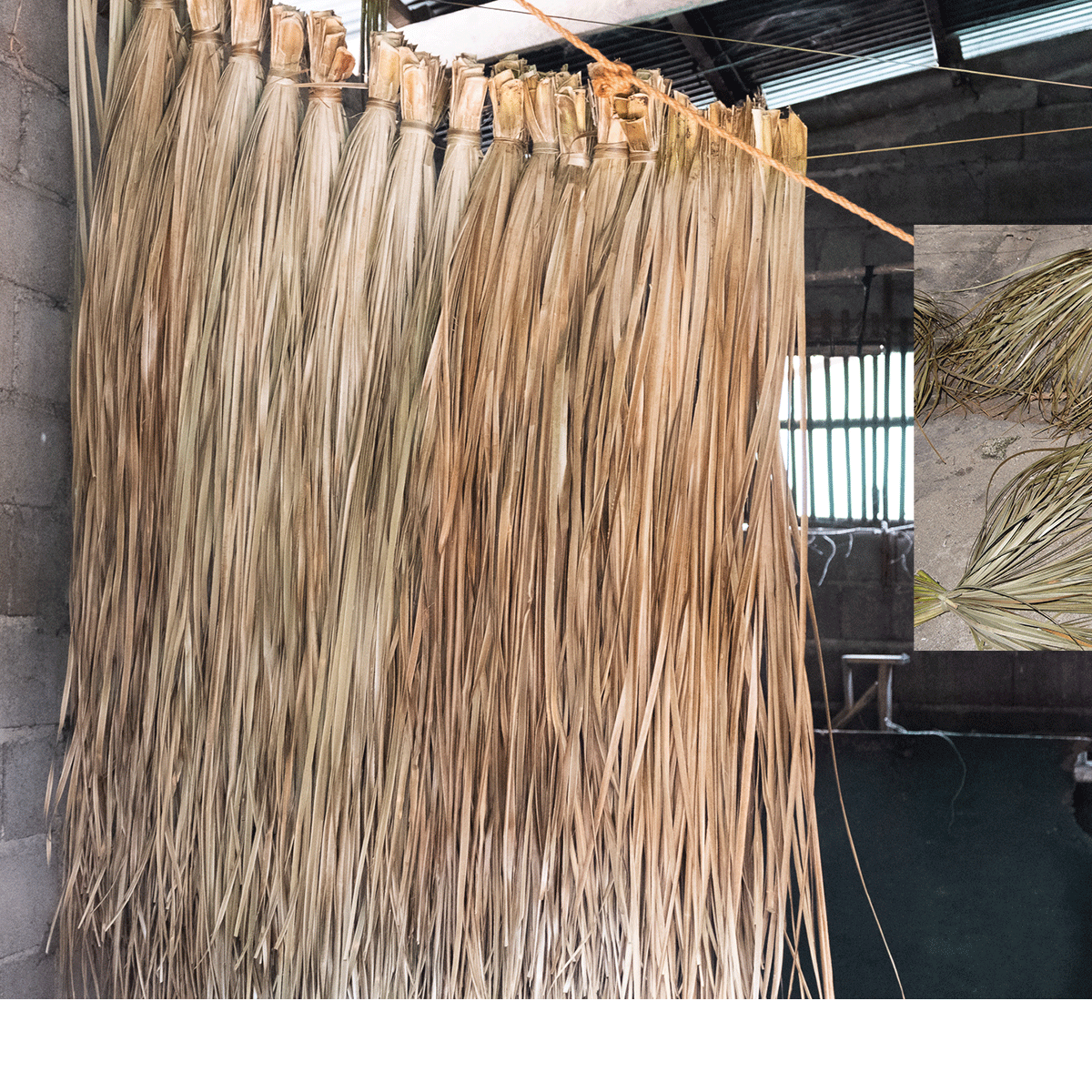

So much of the focus on weaving centers on the intricacy of the patterns created by weavers. However, for a weaver who harvests and processes her own lilas, that's just a fraction of the practice. I've always wondered how my own invented techniques and tools for processing plastics for weaving compared with weavers' techniques of harvesting and processing plants, and I was lucky enough to get a glimpse into what that looks like. I was surprised to learn that some of our techniques were similar, even though I've been learning without guidance. Whether it's in cleaning the leaves or cutting and flattening each strip one by one, there are few shortcuts in preparing the romblon for weaving. It's a tremendous amount of repetitive labor that just has to be done by hand. Mat weaving is deeply tied to local ecologies. All the weavers I met on the island of Leyte weave with rombon, which is a palm-like plant related to pandan. I learned that romblon used to grow abundantly on the coastlines of Leyte for hundreds of years, but no longer does. Some weavers speculated that the increased storms of the changing climate bring too much salinization to the soil, which causes the plants to die off. Because of this, most weavers in Southern Leyte are now sourcing their romblon strips already processed into "lilas" from the small, neighboring islets of Himokilan and Apid. While visiting both of these islands, we saw how the plants actually grow wild near the coast. Weavers demonstrated how the plant is harvested, stripped and dried, and showed us the specialized tools they developed to create equally sized lilas for more consistent weaving. The tools are hand-held or floor mounted with blades made from old sardine tins. Throughout these communities, you can see the long strips of romblon drying in the sun just about everywhere.

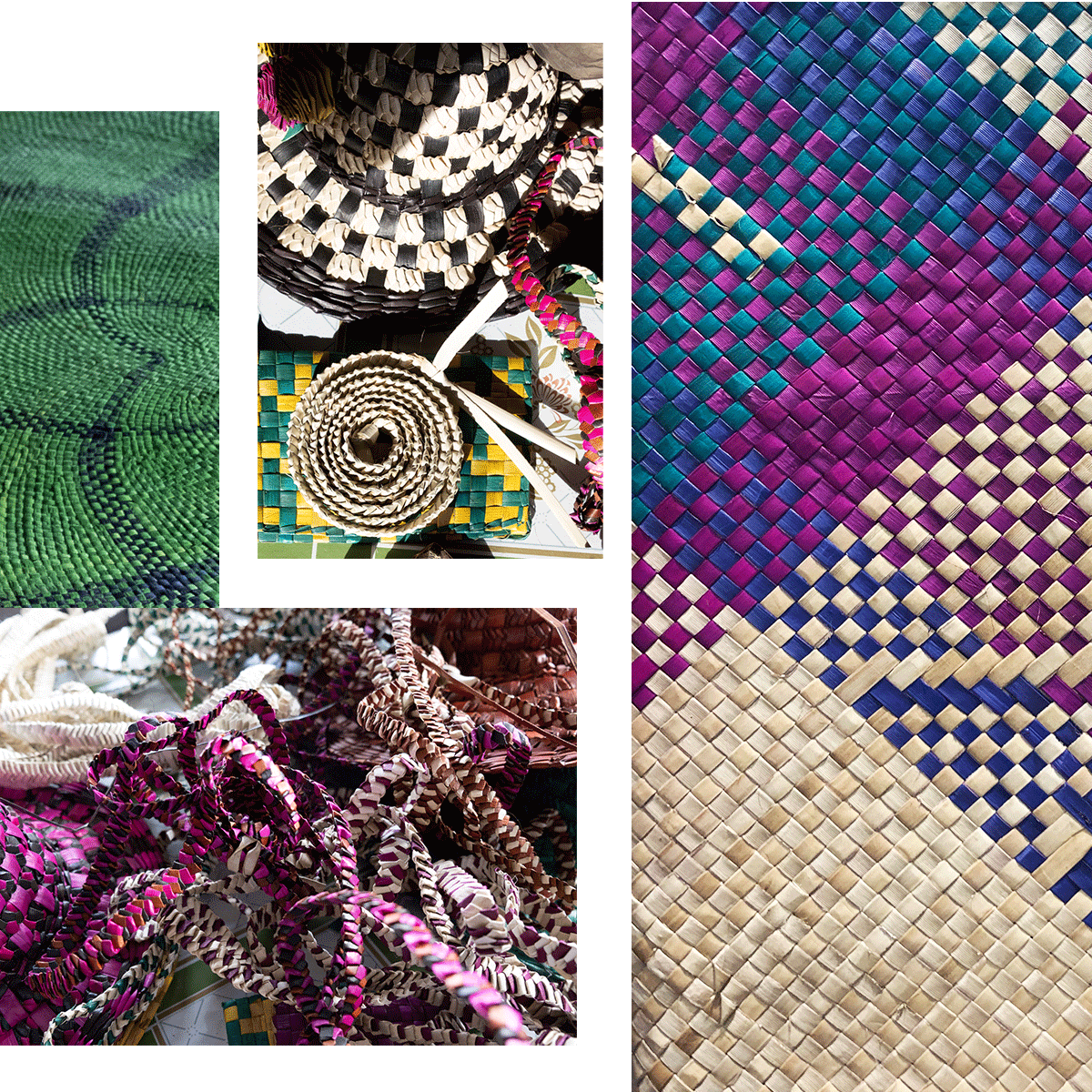

Despite the amount of labor it takes to cultivate, harvest and dry the romblon, the process of preparing leaves for weaving isn’t complete until the strips have been colored. Traditionally, weavers used plants to derive the natural pigments to color the strips, and the plants used to dye lilas were as dependent on local ecologies as the romblon itself. In Leyte, weavers used luyo, kamotes, and bunot —ginger, sweet potato and coconut husk—for pigmentation. Today, all the weavers I visited opt to use strong chemical dyes because it’s the only way to get the intensely vibrant pigmentation that’s popular with clients. While I wasn’t able to participate in dying lilas, I was able to talk with weavers about it. Generally, the weavers in Leyte told me that their color selection is still somewhat based on the colors derived from natural pigmentation, but often it's just based on what's available. Chemical dyes don't necessarily make the process easier. Like every other step along the way, it requires attention and care: a weaver must strive for accuracy in preparing the dye bath, and understand how proportions change for the mass of material. If a mistake is made the dye won’t be colorfast and it will rub off on the skin, clothes and other surfaces, and it will fade rapidly with sun or moisture exposure. One of the key themes that emerged from my conversations with the weavers is that pretty much every step of banig weaving traditions is transforming. Despite these changes, it’s also really clear that each step still requires specialized ecological knowledge and proficiency in practical application. Using color is just one of the ways weavers achieve the incredible patterning they are so famous for. In my own practice of using non-traditional materials to create banig, I sort discarded plastics into different brands, transparencies and rigidities. This process creates a unique color language specific to the location where the plastics were collected, which has the power to reveal a social, environmental and geologic memory embedded within that very materiality.

Pretty much every single weaver mentioned that they make and sell banig with less and less frequency these days. Actually, most weavers won’t start a banig, unless they have a specific order for it. According to the weavers, it takes too long to weave a mat and they don’t make much money on it. For reference, in Leyte a weaver can get around only Php 300-600 for a single size banig—about USD 6-12 for a full day or more of weaving alone. There’s just less demand for banig these days too, with more and more people opting to sleep on foam mattresses instead, or turning to machine woven plastic mats for their perceived durability. Today, weavers opt to produce other products like bags, hats, placemats and wallets. These products appeal to a wider audience, and they are faster and easier to make. A weaver can work on a bag while sitting more comfortably on a chair rather than crouching on the ground as with weaving banig. Plus, it only takes a couple of hours to weave something on the scale of a bag. Because of how significant tourism is within the Philippine economy, there is a demand for these types of products and they are distributed throughout the country as souvenirs. Commercial buyers make it possible for weavers to distribute their products to markets further afield without having to leave their barangay. It can be profitable for weavers, but it also has pitfalls. In addition to being treated as machines to create identical products over and over again, some of the weavers I spoke to had been burned by predatory order. In the past, weavers unwittingly signed contracts with a bulk buyer that specified working timeframes that were actually impossible to meet, and ended up owing money to the buyer. On the flip side, many weavers choose to become part of a social enterprise (SE) or an association of weavers within the community. These organizations can protect them from these kinds of predatory orders by acting as a buffer between the weaver and buyer, by empowering weavers with business knowledge and preserving a weaver’s agency to choose the patterns they will weave, on whatever product they make.

______________________🐌